A man with a budding love for elegance is anxious for answers to the ailing questions. It can be openly said that perfecting one’s appearance translates into functioning in the surrounding world. I think that there are few daredevils who could dispute with this statement which, in fact, is deeply entrenched in the human consciousness. So does it mean that a man hungry for knowledge and exhibiting grassroots initiative is a lone ship sailing the waters of a boundless ocean?! I personally see such an attitude as a prediction of widely understood changes that obviously give credence to a better tomorrow.

The ordeal that we go through when our shopping for a new pair of dream shoes ends in a debacle is immense! We usually tiddle around the stores, where the utmost amiable shopping assistant is trying to talk us into buying a product that is really unremarkable in terms of its quality. A Polish man has already got used to the frequent itinerancy between the store shelves. Usually expecting shoes whose price won’t make you dizzy and whose construction would offer durability at a satisfactory level. As a practitioner, I’m aware that such a correlation is unattainable for obvious reasons. The competition in the footwear industry is unscalable, and the foundation of its functioning is the mediocre knowledge of a potential customer. What can be changed?

GOODYEAR WELTED METHOD

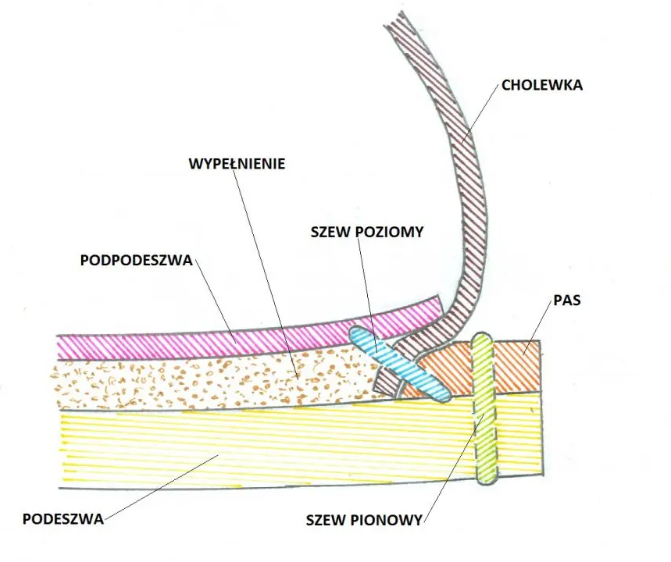

It’s high time to get to the nitty-gritty. Let me start with the Goodyear Welted method that came into existence in the shoemaking craft already 300 years ago. The above method is the best form of shoemaking in the eyes of experts around the world. The production itself is incredibly laborious and time-consuming. Yet, it is a crucial prerequisite to guarantee perfect durability for the user while wearing. Shoes made with Goodyear Welted method are hand-made or machine-made. Each pair of shoes requires individual adjustments, described below.

The shoemaking process starts with cutting the leather part of the upper. Afterwards, the craftsman goes on to the closing, during which different parts of the upper are stitched together. During this stage, a range of activities are implemented: adjusting the leather part if it is too wide or thick as well as dyeing and bending the leather in order to improve its appearance. The next step involves the stretching and forming the upper with a cobbler’s last and attaching the instep and the heel. Before the stretching, the top part of the shoe undergoes appropriate conservation measures in order to get rid of the moisture that would thwart the possibility to appropriately shape the leather.

The welt is an indispensable element of the described method. It is stitched together with the upper and the insole which will be connected to the sole. When the wear of the sole becomes visible, this brilliant process allows for its non-invasive replacement. Another step is sewing the sole to the welt. The sole is attached with threads, owing to which it maintains appropriate durability. The edges of the sole are cut before they are dyed. The method involves manual work and thus, the specialists can display their craftsmanship, which they have at their fingertips. The final stage involves dying and polishing the sole. The icing on the cake is waxing, brushing, and polishing of the shoes.

The above-mentioned process has its strategic purpose, which is more than ten years of comfortable footwear exploitation. Owing to the additional layers, the shoes are resistant to the changing weather conditions that we so much dislike. On multiple occasions, I mentioned the correlation of the shoes with the remaining elements of the outfit. Confident about the advantages of the shoes produced with the described method, I wholeheartedly recommend investing in shoes that will become one with their owner. What may be a discouraging factor is the price itself. Fortunately, Polish market is full of companies that sell affordable products. The technological process itself also uncovers a negative aspect that I need to mention. It is the number of layers that have to be stitched to the upper. It may result in a considerable discomfort in the initial stages of wearing.

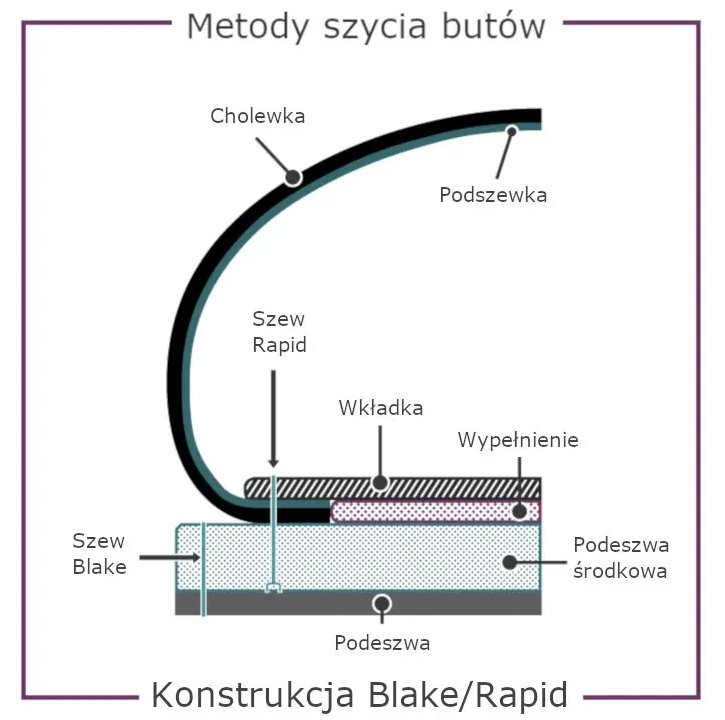

BLAKE METHOD

The Blake method doesn’t have Polish nomenclature, making it more enigmatic to Polish customers. People who are competent in the field have provided a substitute name for the method – a stitch-through method. The production of footwear with the above method is relatively simple. It’s important to pay special attention to the appropriate maintenance and care, owing to which the shoes will be a guarantee of a very long and comfortable product life. On the substantive side, the method itself involves the stretching and forming the upper with a cobbler’s last and fixing it with metal nails or glue to the insole. Once the outsole, filler, and lining are applied, the cobbler’s last is taken out and the upper is stitched to the sole. The described method of sewing shoes didn’t enjoy great popularity in the most buoyant epoch of handicraft, as it was immensely difficulty to get to the shoe tip to apply the stitching.

The technique itself has a wide circle of sceptics, claiming that the construction of the shoes has a relatively low durability which is a result of the main element of the construction – the seam – being subject to mechanical damage. Unfortunately, the results are deplorable and lead to the whole construction falling apart. Intrigued by the fact, I declare that I will conduct an organoleptic test, whose effect will result in my preparation of a post about the experiences connected with this issue on the blog. The comfort and durability are the most important features that footwear should offer. Remember about common sense while shopping and caution in relation to products that initially trigger extreme emotions.